E-MOC is the most advanced heat exchange device.

The airflow enters in the molds from the side and the cooling rate can be repartitioned in the following points:

E-MOC is the most advanced heat exchange device.

The airflow enters in the molds from the side and the cooling rate can be repartitioned in the following points:

The Forming Engineering services provided are:

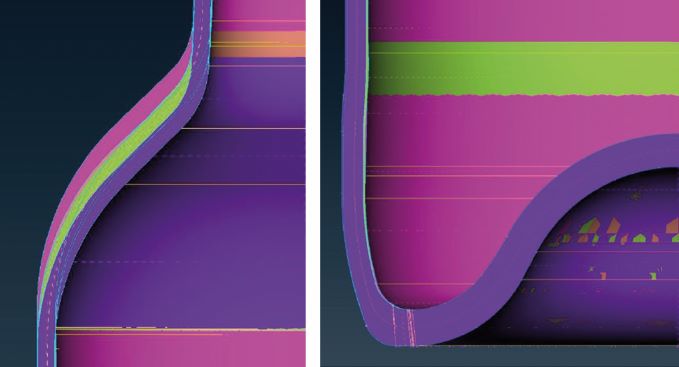

Strength and dimensional qualities are strictly related to glass distribution all over the article. Keywords for glass distribution are:

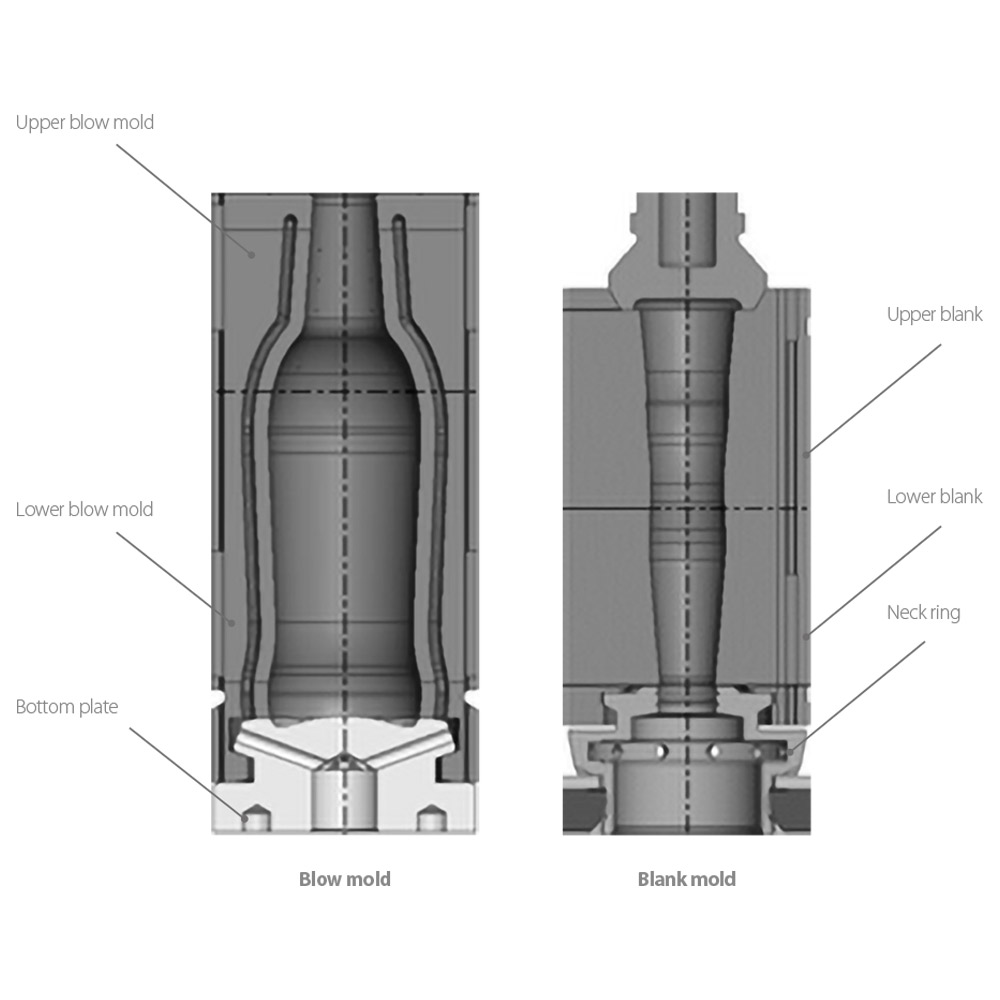

The mission of Mold Engineering service is to supply a “plug&play” mold equipment reducing machine timing settings to control the cooling effect.

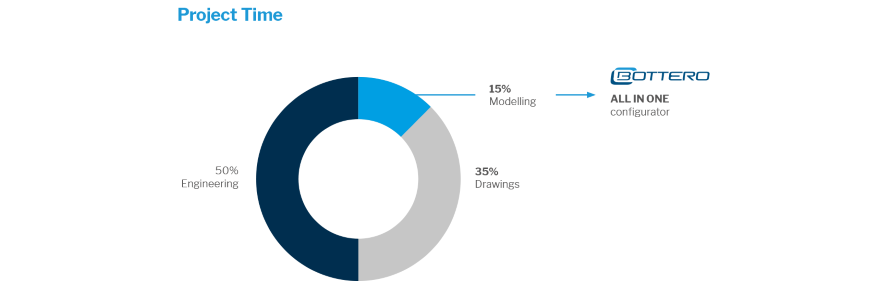

The parison study is done by MS Office excel linked with PTC CREO model. The excel sheet synchronizes the model and receives inputs from the latter to manage shape and control parameters. Given input specifications, the Blank configurator generates the mold in real time.

What ever is the cooling technology whatever available in your plant, the engineering service will supply the most efficient design.

Airflow balancing through cooling duct optimization.

Result:

Cooling capacity balancing between cavities.

FCC with double row cooling channels with fins intercepting the flux.

Result:

Higher heat extraction and better mold temperature homogeneity.

Blank stack cooling optimization to balance air delivery between cavities.

Result:

Lower air consumption, higher heat extraction and better mold temperature homogeneity.

FE team and customers are partner.

They organizes in-Bottero or in-glass factory trainings in order to improve technical skills related on: