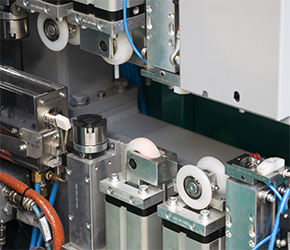

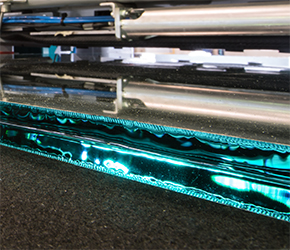

548 LAMIl nuovo modello della gamma Lamilinea, il 548 LAM, nasce dalla lunga esperienza Bottero nel campo dei tavoli di taglio laminato e dai miglioramenti delle soluzioni tecniche dei prodotti Bottero. La macchina Qualità principaliLa gamma di prodotti Bottero dedicati al taglio del vetro laminato copre ogni necessità produttiva in termini di formati e spessori processabili, consentendo di raggiungere eccellenti qualità di taglio persino su lastre da 12+12 mm. Il riscaldamento del PVB viene effettuato da un sistema brevettato di lampada IR di soli 300 mm! Nonostante le piccole dimensioni del dispositivo, il ciclo di riscaldamento è incredibilmente veloce e costante e offre sorprendenti vantaggi per la manutenzione e per i ricambi. |

Richiesta informazioni

Chiudi X

Chiudi X

Catalogo PDF

Al completamento del modulo, riceverà una mail all'indirizzo da Lei indicato con il link per il download del materiale richiesto.