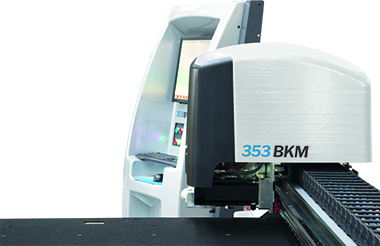

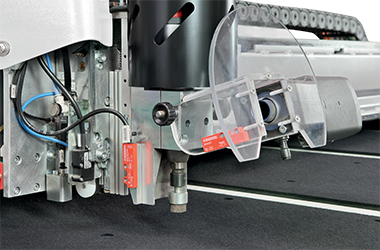

343 BKMLoading, cutting, grinding, marking and breakout table intended for the wider range of applications. Main qualitiesDesigned for glassmakers who want to evolve their business by adopting automated and flexible cutting systems, BKM tables offer all the quality and simple use that is typical in Bottero products. Thanks to the shared single development platform, common to all cutting systems, BKM tables use technological solutions and components that are also adopted on top of the range Bottero systems, thereby ensuring uncompromising performance and reliability.BKM cutting systems can make linear cuts and shapes on sheets with a thickness of up to 19 mm, thereby offering the possibility of making small and medium productions in series and particular pieces.The BKM cutting systems are available both in the standalone version, for loading, cutting and breakout of the material on the panel, and in the fixed structure version for high productivity in-line integration. All models can be equipped with a wide range of accessories.FeaturesEach constructive and functional features of the BKM range is designed to ensure extreme processing precision and maximum productivity, at the service of each specific production requirement.Cutting bridge StructureSteel cutting bridge placed crosswise to the machine for maximum solidity and resistance to torsion.DriveDouble brushless motor with gantry transmission.Carriage handlingHigh precision and low noise carriage linear sliding guides, ground and installed on machined surface.Carriage and cutting head CutMotorised cutting head, formed by an aluminium alloy body and rod with cutting tool or plastic cut. Automatic glass thickness measurement by linear encoder and consequent automatic loading of the cutting parameters preset in the software. Cutting pressure adjusted by means of proportional solenoid valve and glass surface compensation system.SafetyGlass presence detector and end element of the rod with controlled breakage, easily replaceable, to avoid mechanical stresses on the carriage and bridge in case of collision.TrolleyAluminium carriage with control and management electronics of the on-board head, complete with optical sensor able to perform the electronic squaring of the sheet and automatically acquire a shape thanks to the Shape Scanner system.Bridge Handling GuidesHigh precision and low noise bridge sliding guides, ground and installed on machined bed, ensuring a perfectly straight cut without the need for adjustment.RacksGround racks, ensuring maximum positioning and cutting precision, and facing down to prevent the accumulation of dirt.MaterialsComponents made of highly durable and minimal wear materials, ensuring optimal performance over time. Easily accessible components, ensuring immediate and fast maintenance.Technical specificationsWorking speedMaximum bridge speed150 m/minMaximum carriage speed150 m/minMaximum grinding speed with Easy deletion80 m/minAccuracyCutting accuracy on straight processes± 0.15 mmThicknesses which can be cutGlass thickness2 ÷ 19 mmWork tableWorktable height930 ± 40 mmVersions343 BKM RegularDimensions5250 x 2905 mmMaximum dimension of processable sheet3810 x 2750 mm343 BKM JumboDimensions7600 x 2905 mmMaximum dimension of processable sheet6100 x 3355 mm |

Information Request

Close X

Chiudi X

PDF Catalogue

Upon completion of the form, you will receive an email at the address indicated by you with the link for downloading the requested material.