343 BCS

Tavolo di taglio, molatura e marcatura completamente integrabile con moduli di carico e troncaggio manuali o automatici, destinato ad applicazioni che richiedono alta produttività. Il tavolo di taglio 343 BCS è fisso e

completo di trasporto con cinghie, selezione automatica delle pressioni di taglio, Shape Scanner + Scan Cad,

ottimizzatore a bordo macchina e BCMS Windows.

Qualità principali

I tavoli di taglio BCS sono progettati per sostenere carichi di lavoro elevati tipicamente adottati nella produzione, anche su più turni, di serramenti o rivestimenti, nel settore dell’arredamento, nella lavorazione di componenti per elettrodomestici, nel settore automotive, e in numerosi altri ambiti. I banchi da taglio BCS Bottero sono tra i più diffusi ed apprezzati al mondo, costituendo per capacità produttiva ed affidabilità, un vero punto di riferimento nel mercato. I

L’elevato standard qualitativo della gamma BCS è particolarmente percepibile nella cura dei dettagli: ogni componente è attentamente studiato e progettato per offrire prestazioni all’altezza dei requisiti più esigenti, rendendo la macchina ancor più sicura e performante.

La gamma BCS si contraddistingue per la sua modularità e versatilità, grazie alle quali i tavoli di taglio float possono essere totalmente configurati in base alle specifiche esigenze del cliente: da tavoli di taglio stand-alone destinati a produzioni ridotte, fino a sistemi di produzione intensiva ad alto livello di automazione, completamente integrabili con dispositivi di molatura Low-E e marcatura, e con moduli di carico e troncaggio.

Caratteristiche

Con l’obiettivo di soddisfare ogni tipo di necessità produttiva, i tavoli di taglio BCS permettono di installare sul carrello di taglio anche uno dei vari dispositivi accessori disponibili. Ogni caratteristica costruttiva e funzionale della gamma BCS è studiata per garantire estrema precisione di lavorazione e massima produttività, al servizio di ogni specifica esigenza produttiva.

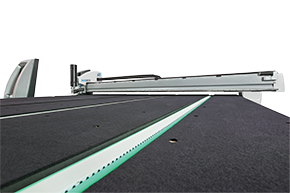

Ponte di taglio

Struttura

Ponte di taglio posto trasversalmente alla macchina e realizzato in acciaio per una massima solidità e resistenza alla torsione.

Motorizzazione

Singolo motore brushless con trasmissione a cinghia motore pignone.

Trasmissione

Albero di torsione per trasmissione del moto lungo il ponte accurata e bilanciata.

Movimentazione carrello

Guide lineari di scorrimento carrello ad alta precisione e bassa rumorosità, rettificate e installate su superficie lavorata a macchina.

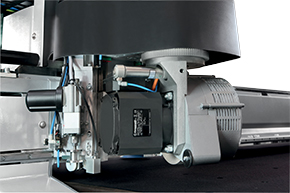

Carrello e testina di taglio

Taglio

Testina di taglio motorizzata, costituita da corpo in lega di alluminio e stelo completo di utensile di taglio o taglio plastico. Misurazione automatica dello spessore vetro per mezzo di encoder lineare e conseguente caricamento automatico dei parametri di taglio preimpostati a software. Pressione di taglio regolata per mezzo di elettrovalvola proporzionale e sistema di compensazione superficie vetro.

Sicurezza

Rilevatore di presenza vetro ed elemento terminale dello stelo a rottura controllata, facilmente sostituibile, per evitare sollecitazioni meccaniche sul carrello e sul ponte in caso di urto.

Carrello

Carrello in alluminio con elettronica di controllo e gestione della testina a bordo, completo di sensore ottico in grado di effettuare la squadratura elettronica della lastra e di acquisire automaticamente una sagoma grazie al sistema Shape Scanner.

Movimentazione Ponte