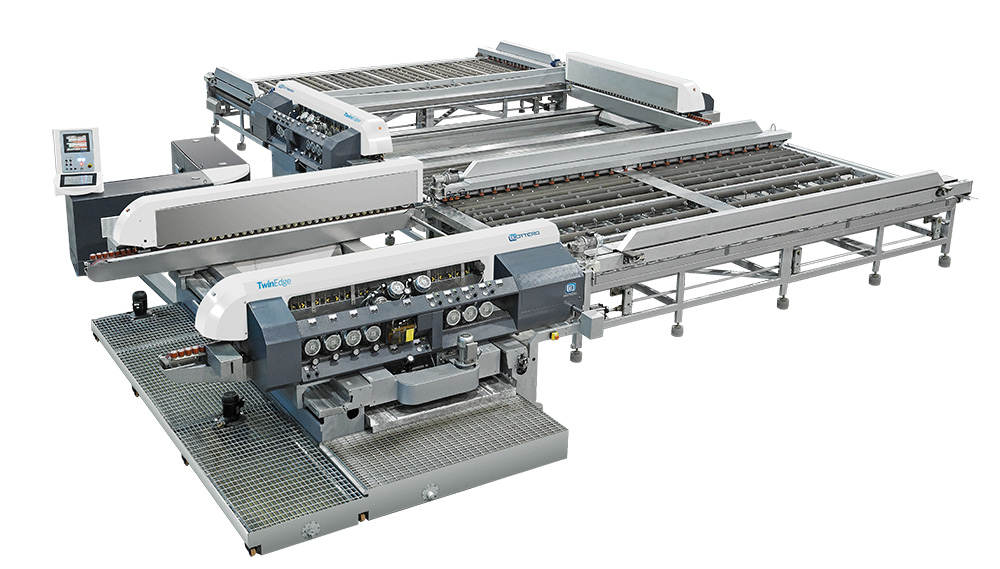

Twin EdgeThe 4 configurations that make up the Twin-Edge range enable the processing of flat edge, of threads and possibly the removal of the edge. Main qualitiesLa gamma di bilaterali per la lavorazione del filo piatto Bottero è stata progettata per The Bottero range of double edgers for flat edge processing has been designed to meet all requirements of performance and quality.The 220 N is the classic double edger designed for who needs to produce large quantities of glass with precise orthogonality, which vertical machines are not able to offer. Its configuration has, on each side, 3 diamond wheels and 3 polishing wheels for flat edge and 2 diamond wheels and 2 polishing wheels for threads.The 222 D is ideal for customers who need to grind with large removal of material. Its configuration has, on each side, 4 diamond wheels and 3 polishing wheels for flat edge and 2 diamond wheels and 2 polishing wheels for threads.The 224 N is the highest performing machine of the Twin Edge range. Its configuration has, on each side, 4 diamond wheels and 4 polishing wheels for flat edge and 2 diamond wheels and 2 polishing wheels for threads.Features Why Choose Them? |

Chiudi X

PDF Catalogue

Upon completion of the form, you will receive an email at the address indicated by you with the link for downloading the requested material.